Z-Axis Modes

The PUMOTIX system with the “Oxy-Fuel cutting (4 axes)” module supports working with the Z axis in three modes:

- external Z control;

- Up/Down control;

- manual control.

The selection and adjustment of the operating mode is carried out on the tab “Configuration” → “Settings” → “Oxy-Fuel”.

Window "Settings" of the oxy-fuel module

External Z Control

This mode involves the use of a stand-alone flame torch height controller (CHC-400 and others). The Z axis (including the motor) is controlled in this mode by the autonomous axis controller.

To ensure interaction with an external autonomous axis, the following set of signals is used in PUMOTIX:

- Control signal output Up

It is connected to the UP input of the autonomous axis controller and serves to signal the torch moving up. - Down signal output

It is connected to the DOWN input of the autonomous axis controller and serves to signal the torch moving down. - Correction signal output

Signal for controlling the torch height of the gas torch. It is connected to the AUTO/MAN input (for the controller of the autonomous axis CHC-400) and is used to transfer the controller of the autonomous axis to the mode of automatically holding the set height. The output automatically switches to the active state when the “Z-Axis Correction” option is enabled. The correction signal output can be manually activated or deactivated using the corresponding button on the “Diagnostics” tab → “Controls” → “Correction signal output”: On/Off. - Collision Signal Input

The collision signal input actually represents the Stop signal input. This signal is recommended for use with the output signal Collision (collision) of the autonomous axis. Having received a signal about the collision of the measuring ring with metal or machine structures, the PUMOTIX control system will stop the execution of the control unit without losing coordinates. After eliminating the conflict, the execution of the G Code can be continued from the place of stop. - LimitHight Signal Input

The OxyExternalZLimitHight signal is used to interact with the sensor of the extreme upper position of the torch of the autonomous Z axis (if such a sensor is present). When using a sensor, the PUMOTIX control system raises the Z axis until a signal is received from the sensor. Lifting is carried out for safe movement of the torch between cutting contours, as well as when you click on the “Stop” button with the active option “Allow Safe_Z moves”. Signal settings are on the “IO” tab.

Up/Down Control

The mode is designed to control the torch torch height using the UP/DOWN protocol. Used with an external oxy-fuel cutting height controller that generates UP/DOWN control signals. In the absence of an external height controller, a circuit with two buttons connected to the PLCM controller inputs can be used.

The following signals are used for the operation of the mode:

- Sign Up

The input responsible for correcting the cutter up. Connects to the UP output of an external torch torch height controller. If there is no controller, a manual control button can be connected to the input according to the operating instructions to the PLCM controller. - Entry down

The input responsible for correcting the cutter down. Connects to the DOWN output of an external torch torch height controller. If there is no controller, a manual control button can be connected to the input according to the operating instructions to the PLCM controller.

Manual control

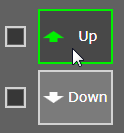

Used in the absence of both standalone Z axis controllers and torch torch height controllers using the UP/DOWN protocol. Correction of the torch height above the metal in this mode is carried out manually using the "Up" and "Down" buttons.

Buttons for height correction in manual mode of the Z axis

In manual control mode, no additional input and output signals are required. When you press the Up and Down buttons, the Z axis moves with the specified height adjustment speed.