Automatic zoned down draft air table control

The "Automatic zoned down draft air table control" feature is developed to ensure optimal operation of the plasma cutting machine. It requires a specific configuration of the machine. Therefore we recommend you make sure that your CNC machine configuration can work with this option before purchasing it.

Aspiration table control module includes a set of functions and optimizations of the smoke removal process. It developed on the basis of the wishes of the plasma cutters. Machine logic does not require the acquisition of additional options and implements a fairly complex algorithm. This logic could not be implemented using classical or background macros.

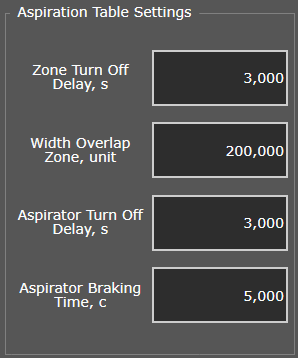

You can set the delay time for closing zone after switching to the neighboring one. The overlap width is set for the most efficient operation of the hood when it is in the overlap zone. The delay for turning aspirator off allows to increase the fan resource. It begins to be counted from the moment the G-code is completed, i.e. excludes fan shutdown at idle crossings. The last zone will be closed only after the fan stops completely. It's also configured by a parameter in the interface.

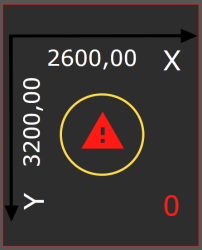

In addition, manual exhaust control is supported. The interface also has indicators of the current status of the output. In case it is not possible to control the exhaust table (for example, when the homing was not performed and machine coordinates were invalid), the system displays a warning message.

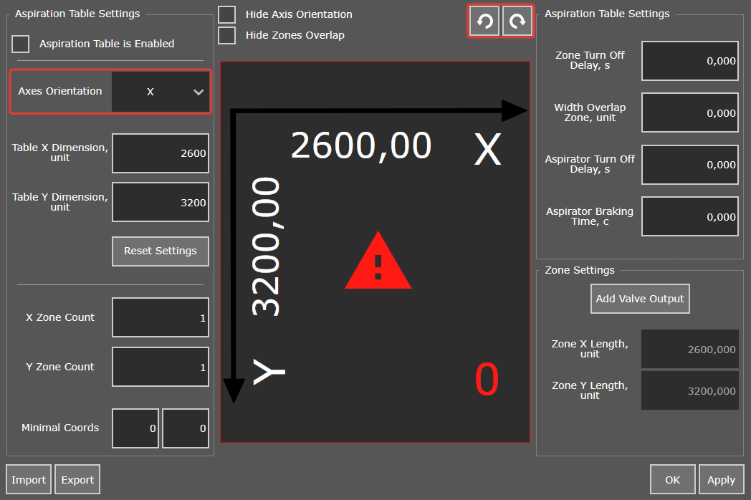

Aspiration Table Settings

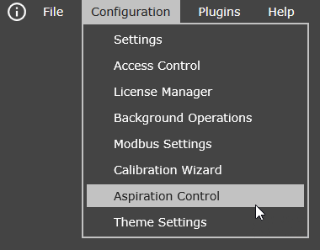

Open settings manager: "Configuration" → "Aspiration Control".

Next, follow the steps below to configure.

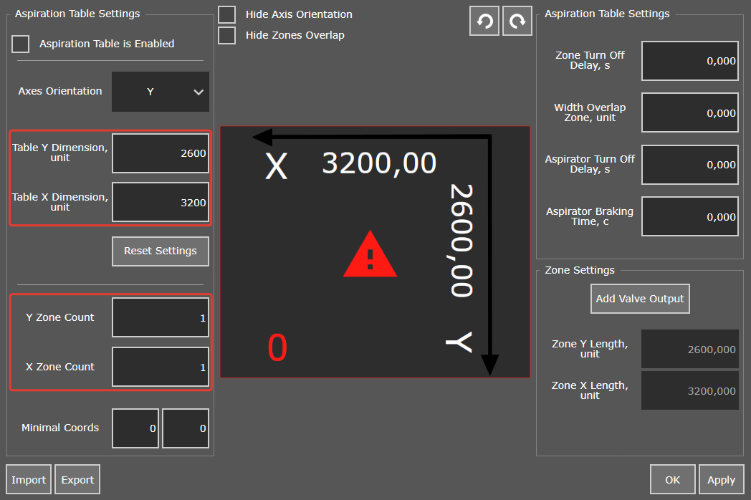

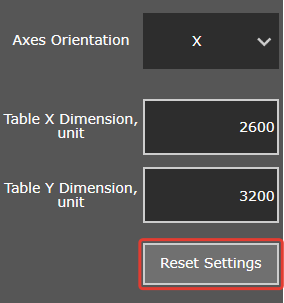

- Position the table so that the axis directions correspond to the real CNC machine. Rotate and change axes using the rotation buttons and a drop-down list with main axis. Perform the necessary actions until the picture matches the representation of the your CNC machine.

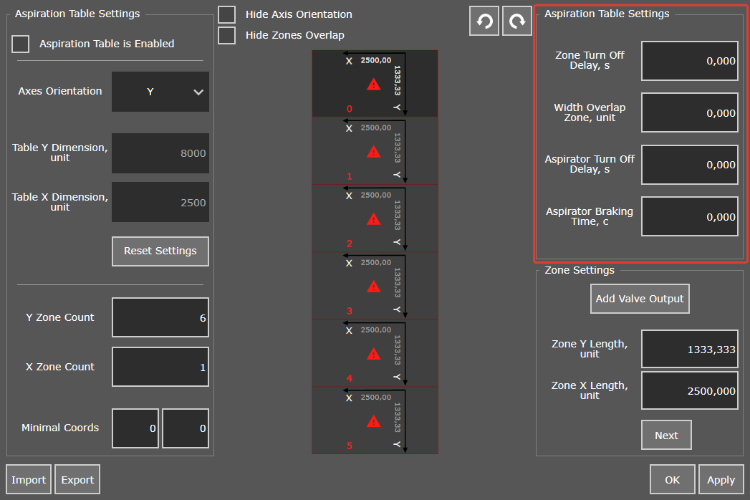

You can see a red “Attention!” sign in the center of the table. It indicating that the zone is inactive because not all the necessary configurations for its operation are configured.

- Enter the dimensions of the CNC machine and indicate the count of zones on each axis. PUMOTIX will automatically calculate the width of each zone. You can adjust the size of the zones to match the real ones in the one of the next steps.

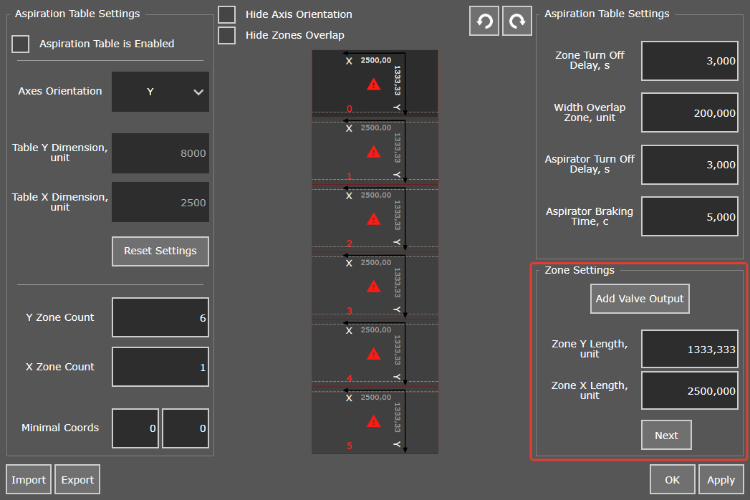

- Add delay to close the zones and the aspirator turn off delay so that the program helps to avoid damage to the equipment. Also set the width of the overlap zone for the most optimal transition between the zones, unless otherwise specified by the CNC machine configuration.

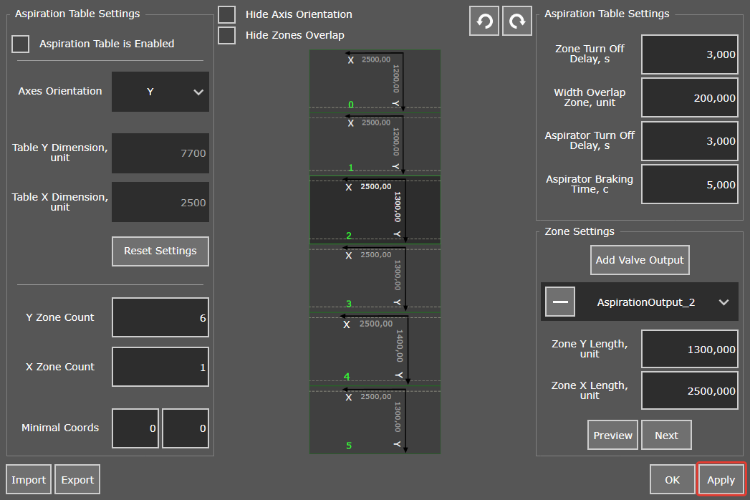

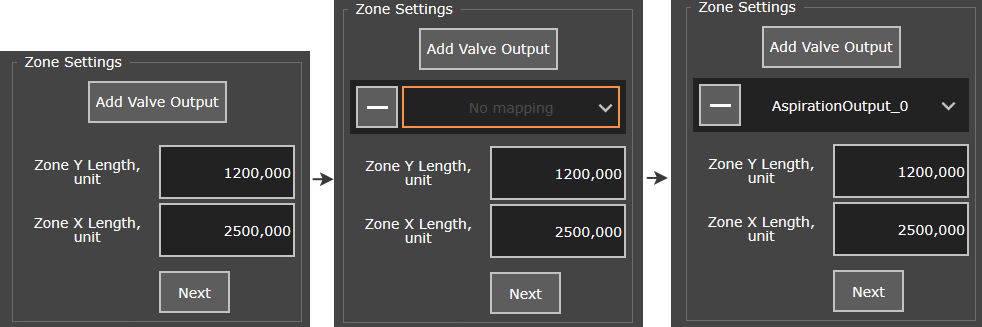

- Customize each zone using the zone navigation buttons. Add necessary user-specific outputs for the valves andadjust the zones dimensions to match the actual ones. Use the "Add valve output" button to add a valve output.Select the desired output in the field that appears. Please note that each output of the valve must correspond to areal output in the signal settings.

- Click the "Apply" button to save the settings.

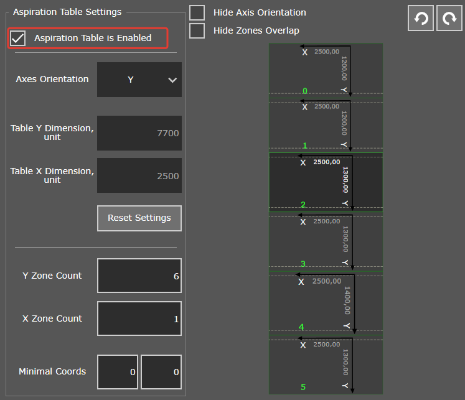

- Activate the aspiration table.

The indicator of the table ready to work will appear on the main screen after activating the exhaust table. Also the buttons for manually turning on the aspirator will appear on the main screen in the "Workflow" and "Diagnostics" tabs.

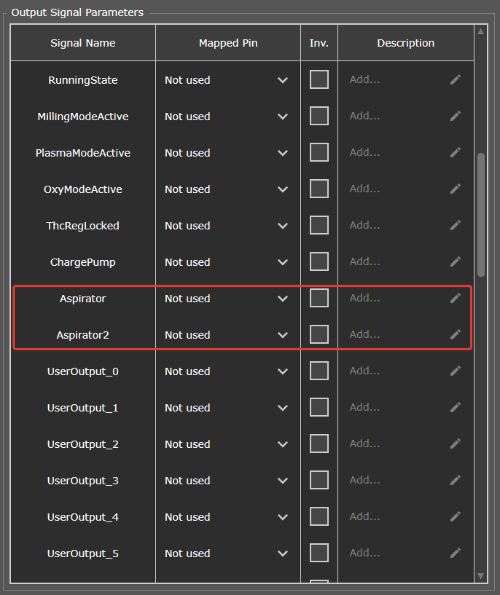

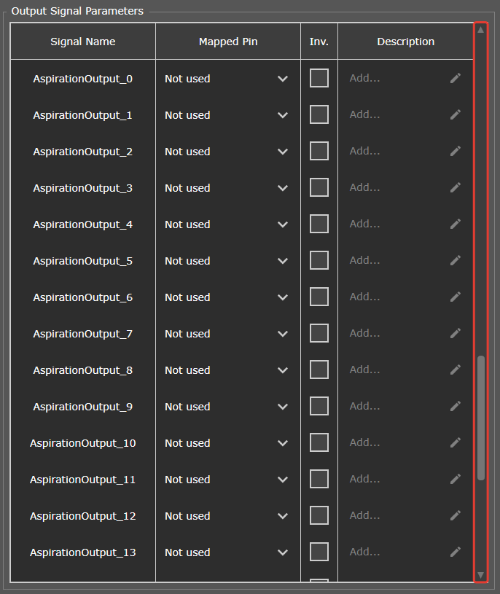

Configure the aspirator outputs to complete the setup. Select: “Configuration” → “Settings” → “Signals” and assign the required count of outputs for the aspirator.

You can observe the further operation of the algorithm during the execution of the control program on the "Diagnostics" tab where there is an indication of the outputs for the valves and aspirator.

Additional Information

"Attention" sign in zone settings

You can see a red “Attention!” sign in the table settings in the center of the zone. It indicating that the zone is not active because not all the necessary configurations for its operation have been configured.

The following settings are required for the zone to become active:

- zone length along X;

- zone length in Y;

- zone valve output (at least one).

The dimensions of the zone are set automatically when marking the table. But it can be adjusted in accordance with the actual dimensions of the zone. The zones will turn green and the “Attention!” sign will disappear after adding the valve outputs. It means that all the necessary settings for the operation of the zone have been received.

Valve outputs settings

The aspiration table settings window assumes the settings of the valve outputs for each zone. Click the "Add valve output" button to assign an valve output. Than select the desired output in the field that appears. Please note that any required count of valve outputs can be assigned to each zone.

It is necessary that each output corresponds to the real pins of the controller outputs for correct operation. To configure them, go to the menu item: "Configuration" → "Settings" → "Signals". Then configure the pins for the assigned outputs in the "Output signal parameters" section.

Delay and overlap settings

The settings for the closing delays and the size of the overlap zone affect the operation algorithm of the aspiration table control. Therefore it is so important that these parameters are non-zero.

The zone closing delay time is the closing delay after moving from one zone to another. A non-zero value of the parameter allows you to suck out the remnants of smoke in the previous zone before it closes while the valve of the next zone will already be open.

The width of the overlap zone allows you to specify the size of the zone which (to increase productivity) the valves of two or more adjacent zones will be open. If the parameter is non-zero the zone closing delay time is counted after leaving the overlap zone. For clarity, the boundaries of the overlap zones are indicated by a dashed line on the table scheme. Please note that the size of the overlap zone should not exceed the size of the aspiration zones.

Fan turn off delay time is the shutdown delay after the completion of the control program or stopping the machine. A non-zero value allows you to remove the smoke remaining from the last performed operation before completely shutting down the machine.

The aspirator stop time is the time it takes the aspirator to stop completely after receiving the stop signal. If the parameteris non-zero the last zone will be closed only after a complete aspirator stop. It will help to avoid the vacuum effect andprevent possible damage to the CNC machine caused by this effect.

"Reset Settings"

The “Reset settings” button can bring the table settings to the default settings without affecting the delay values and the size of the overlap zone. The table will become one zone after pressing the button. All partitions will disappear, the direction of coordinates and the assigned valve outputs for the zones will be reset. It is recommended to use the button only if necessary to radically change the table layout.

Import and export settings

The settings window is equipped with the "Export" and "Import" buttons to transfer settings between devices. They allow you to save the table configuration file to the user's computer or load the existing configuration file.