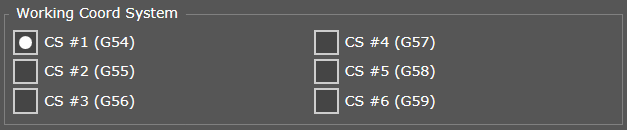

Working Coordinate Systems

The PUMOTIX system supports the use of several working (operator) coordinate systems. The control program is executed in the selected working coordinate system. If the control program is completed with the M30 command, PUMOTIX switches to the default coordinate system — G54.

The choice of the working coordinate system is carried out using the G-codes G54-G59, both prescribed in the control program and entered in the MDI of the system. In addition, the user can define the default working coordinate system in the system initialization line (“Configuration” → “Settings” → “G-code”).

Choosing a default coordinate system

When preparing the machine, the operator can be guided by the following approximate sequence of actions:

- Before carrying out the work, being guided by the dimensions of the used workpieces and the capabilities of the machine, determine and mark on the working field of the machine a point (0W1), which will be used as the working zero for the first working coordinate system (by default, the coordinate system selected by the G54 code).

- Perform an automatic homing (if there are home sensors) or set the machine zero manually (if there are no home sensors).

- Use the manual keys to move the tool to the point defined in paragraph 1 and set the working zero by resetting operator coordinates along all axes using the corresponding interface commands. If you need to use several working coordinate systems, you can repeat the procedure to determine the remaining working zeros (0W2), switching between coordinate systems using the G54-G59 commands entered in the MDI of the system.

The location of the working zero will be maintained between work sessions until the new zero point is redefined for the selected coordinate system.

In fact, the coordinate on any axis in the selected working system is defined as the sum of the machine coordinate on this axis and the corresponding offset:

XW1 = XM + ΔXW1 (XW1 is the current coordinate on the axis in the working coordinate system, XM is the machine coordinate on the same axis, ΔXW1 is the offset on the same axis for the selected working coordinate system)

The offset parameters for all working coordinate systems are automatically saved between work sessions, which saves the operator from the tedious operation of setting the working zero on the desktop using the keys to manually move the tool after each turn on of the machine. It is recommended, however, to perform a homing operation after each power-on of the machine or emergency stop during the execution of the G-code using the equipment on/off button.