Perform Preparation Move

In the process, the need periodically arises to stop the execution of the G-code, perform technological operations while moving the tool, and return to the original path. You also often have to run the G-code not from first, but from a specific line, for example, to process one of several blanks contained in the G-code. PUMOTIX software solves both of these problems, allowing you to continue executing G-code from an arbitrary line without losing coordinates.

Preparation movement is carried out from the current position to the beginning of the selected line, i.e. actually to the end of the previous line. For example, in the G-code

N99 G0 Z30

N100 G1 X200 Y300

N101 G1 X250 Y300

N102 G1 X250 Y400

we will select line No. 101 and press "Start". The Preparation movement to the point (X200; Y300; Z30) will be performed and the execution of the G-code from line No. 101 will continue.

An example of the preparation movement

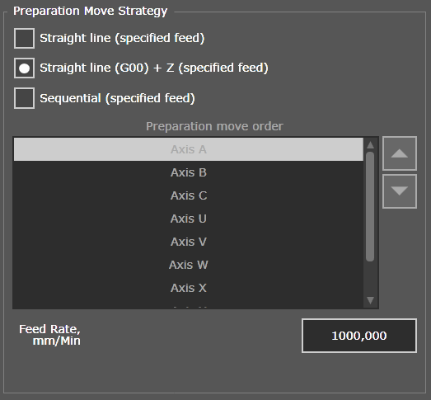

PUMOTIX allows you to select a preparation move strategy:

- in a straight line (with a specified feed);

- in a straight line (G0) + Z (with the specified feed);

- sequentially (with the specified feed).

Choosing a tool return strategy

Preparation movement "Straight line" with the specified feed is carried out immediately on all axes with a predetermined return feed. Those. The tool will move to the beginning of the selected line, choosing the shortest path along each of the axes of movement.

Moving "Straight line + Z" occurs sequentially along the X, Y, A, B, C, U, V, W axes at fast feed, and then along the Z axis - at a given feed.

"Sequential" movement is carried out in the order set by the user. By default, movement along the A, B, C, U, V, W axes will be performed first, then along X, Y, and lastly along Z. The feed will be carried out at the set return speed.

The figure below shows how, when starting the G-code execution from the specified line (path 4), the X moves first (line 1), then Y (line 2), and then the spindle goes down Z (line 3) to the beginning of the selected strings.

The sequence of movement of the tool along the axes during the preparation movement

The choice of the tool return strategy is carried out in the “Settings” tab “Tool” → “Preparation Move Strategy”. There you can also set the feedrate with which the preparatory movement is carried out (1000 mm/min by default).

In any case, the operator, after stopping the execution of the G-code, must manually raise the tool along the Z axis, perform the necessary manipulations, then set the tool at a safe height above the point where the preparation movement will be performed (approximately so that there are no obstacles when moving along X and Y) . After that, you can click the "Start" button.